|

Catlypso - Michael & Kelly McFadyen's Sailing Adventures

Latest update 26 March 2015.

This page is about our preparations for when we set sail from Sydney in our yacht, Catlypso. Our plan at the moment is to leave Sydney on 4 May 2014 and be away for at least six months. We intend to head north along the New South Wales coast and then north along the Queensland coast with regular excursions out to the Great Barrier Reef.

We have no idea how far we will get, but we may make it to Cape York (for non-Aussies, that is the pointy bit at the top right of Australia). We at least want to get to the Cooktown/Lizard Island area.

Along the way we plan to scuba dive wherever we can, but particularly at places like the wreck of the SS Yongala off Townsville and Lady Musgrave Island.

|  |

| Pieces of Eight (as she was called then) under power | Catlypso in South West Arm, Port Hacking |

This blog starts on 1 December 2014 and will be updated regularly. You can read in detail about Catlypso by clicking here.

4 December 2014

Today Michael did the exam for his Marine Radio Operator's Certificate of Proficiency (MROCP). This is a very stupid exam, which asks many questions not related to the use of HF or VHF radios (eg how long does a battery last for an EPIRB, what is the name of the ground station that receives EPIRB messages). You also need to find an invigilator (the person who supervises the exam). Luckily there was one near me, but in the country you could have big problems.

In addition, the cost of $74 to do the exam (this does not include the invigilator's time etc - not sure if they can charge, but it was free) is a big disincentive for what should be considered a mandatory safety item. He really only did the exam (using a VHF radio without a licence is an offence in Australia, but we would guess that less than 1% of people who use have a licence) to enable us to get an MMSI number for our VHF and AIS. Another reason was we have a HF radio and will want to use it in 2016 and you need a call sign for this.

The exam consisted of 50 multiple choice questions and took about 25 minutes.

6 December 2014

Michael has been researching for well over a month how to integrate our Raymarine instruments into our other instruments and our laptop navigation software. After looking at many high cost solutions, he decided to use Seatalk/NMEA-0183 Bi-directional Bridge from Yapp Electronics in the UK. This cost 36 pounds delivered to Sydney, say AU$72.

This takes the Seatalk output from the wind, depth and speed instruments and converts to NMEA and serial. It also has an NMEA input as well.

We also need a Seatalk cable to connect the last instrument in the chain to the bridge (not sure what happened to the one that should be there, could not find it). We purchased a short cable from Arnold's Boat Shop in Melbourne (Seatalk Cable. This cost about $50 delivered. We will cut this in half, so will end up with a spare that we might try to resell on Ebay.

We also needed a serial to USB converter so that the output could be linked to the laptop. Michael found a place in China via Ebay selling cables for less than AU$2 delivered. We purchased two as he figure we can use the other to connect our Garmin GPS128 to the laptop so we can upload and download my diving GPS co-ordinates. Another item we decided to get was a 12 volt laptop power supply. Michael found one on the internet that can do multiple voltages (mine are 12 volt) with different plugs. It was less than $40 delivered.

We ordered all of this stuff by the end of the day.

13 December 2014

Kelly and Michael went out to Catlypso as he was not diving due to bad weather. When we were at the wharf, we met the bloke who owns the boat where our mooring is going. He told us the problem with moving his mooring to its new location was that the company he originally contracted to do it failed. They lifted the first block, but could not lift the second and third ones. He has now contracted the same company we are using. He has no idea why it has not yet been moved.

Anyway, we took out 80 litres of water, food and drink and other items.

15 December 2014

On this day Michael found out that he had passed his radio exam, so now all we have to do is wait for the paperwork to arrive. Hopefully it might turn up this week so he can submit our MMSI application before Christmas.

We also received the laptop power supply and the serial to USB converters. We also purchased two new fenders. Two of the ones we have are broken. They no longer hold air and are not repairable. We will keep the old ones as they still provide some protection.

16 December 2014

Michael took lots of things out to the boat today. This is in preparation for our 10 day trip which will start 26 December 2014 (to Sydney Harbour, Pittwater and Hawkesbury River). He took out 92 litres of diesel, 60 litres of water (tanks are full already), the new fenders, food, drink and some other items. He also tested the 12 volt laptop charger and found that there was not a plug big enough to fit our main laptop. It worked with the netbook, so looks like we will need to make up a plug from a faulty 240 volt power supply.

17 December 2014

Today we got Michael's Marine Radio Operator's Certificate of Proficiency in the mail. That was pretty quick. He went on-line and completed the application for an MMSI number via the AMSA web site (well, it is not actually that site but a related one AMSA Beacons). No problems except he could not put HF radio down as he discovered he needed to get a licence from ACMA (as distinct from AMSA). By 5 pm the same day, the MMSI number had been allocated. For reference, it is 503019080 and you can search for us on any AIS web site (eg Marine Traffic). Very efficient service.

The ACMA (Australian Communications and Media Authority) web site is perhaps the worst we have ever seen. It sends you around in circles, has 10 pages when one would suffice, refers to pages or documents but provides no links. After almost an hour, Michael finally found how to apply for a licence. Well, he thinks he did. He is still not sure what licence is needed as there is no simple explanation. It is assumed he needs a ship class C unassigned, but this could be wrong!

Anyway, you cannot apply on-line, so he downloaded the form. He then spent another 20 minutes trying to find out the cost of the licence. He finally deduced that it is $52 for a year and $100 for two years (discount for multiple years is $2 a year - wow). However, you can only pay (according to the form) by cheque. Who the f**k uses cheques in this day and age? Michael thinks he has not written a cheque for at least seven years, we do not even know if he still has a cheque book. We will apply for this next year sometime. (PS Michael later did a search and found that he may be able to pay via a bank transfer but this is not clear).

The same day the Seatalk cable arrived from Arnold's Boat Shop. Now all Michael needs is the bridge which hopefully will arrive before Christmas.

18 December 2014

Today Michael went out to the boat and put the generator back on board as well as two five litre containers of unleaded petrol for the generator and/or tender outboard. As well, he set up the AIS by uploading the MMSI number and boat details. Although it appears to be showing that the AIS is now transmitting information, we have yet to be able to find our boat on any of the web sites that show AIS targets. Not sure why this is happening, unless our location is not conducive to the one receiver we have found which is located at Kurnell.

Michael later checked via another web site that uses satellites to record AIS data. This site is not live and about 4 hours after it was installed, it came up on that site. Fantastic! It is also visible on another web site, Marine Traffic. We have since worked out that sometimes our location does not come up on the AIS sites. This appears to be weather related.

21 December 2014

We went out to Catlypso today, mostly just to take more food out for our trip later in the week. The batteries were full, even though for most of the week the fridges and freezer have been running with lots of stuff in them. Michael left the AIS running as he wants to upload some photos to the site mentioned above and he thinks we need it to be visible for this to happen. Michael also attempted to set up a bluetooth dongle on the laptop so that we can stream songs to the radio. However, the driver he took did not work. Back to the drawing board on this one.

23 December 2014

Today we found out that our mooring was now in place. Unfortunately we are heading off tomorrow to the Gold Coast to spend Christmas with Kelly's family, so we cannot go and move Catlypso to the new mooring. On 26 December 2014 when we return, we are heading off sailing for 10 days, so it will not be till about 3 or 4 January 2015 when we can try out the mooring (we later decided not to use till mid-January).

28 and 29 December 2014

When we came back from the Gold Coast, we headed off for Broken Bay which is the waterway on the northern outskirts of Sydney. While up there we did a lot of work on the boat, especially on the first couple of days. Michael totally cleaned the topside of the boat and then polished with cutback the smooth surfaces. Looks a lot better. Meanwhile, Kelly cleaned out the port bilges and while doing this she found a tarp which we think is a sunshade. We later set it up, works perfectly. Click here to read about that trip.

|  |

| The "new" sun shade in place | Another shot of the sun shade |

Today Michael decided to check out the solar panels as he suspected that at least one was not working properly. By putting a newspaper over each of the panels in turn and watching the amp output, he discovered that the third panel from the left (as you look at it) on the tender davits was not working.

After checking the panel output (good) and the solar regulator (bad) he finally found that there was a connection under the rear cockpit seat. Here the positive wire had pulled out of the connector. Michael fixed this, but he had killed the fuse in the regulator during the testing. We texted our friend Greg who was coming aboard New Years Eve to see if he could find some 7.5 amp fuses as there were none on board.

31 December 2014

Greg arrived and the 7.5 amp fuses got the solar panel back working. Michael also looked at some of the other connections and in the end we seem to now get about 30 amps into the batteries when the battery charge is about 600 amp hours. It seems that there is another regulator that controls the output of the solar panel regulators (or perhaps it is these regulators themselves) and the input drops from about 30 A at 600 A/h to 15 A at 700 A/h.

It was also noted that when a drain is put on the battery at (say) 700 A/h by the freezers coming on or the 240 volt inverter working, the input can stay at 15 A despite the outgoing amps.

5 January 2015

Today we purchased a jiggler siphon hose so we can more easily transfer diesel from our containers to the main tank. We also purchased a small plastic paint scraper for removing minor growth on the hull. Michael got some more 7.5 A fuses as he killed a few when testing the other panels.

When we got home from the trip we found that the Seatalk/NMEA-0183 Bi-directional Bridge from Yapp Electronics had arrived from the UK. Now Michael just needs time to install all the bits so that the Raymarine data is shared with the laptop etc.

9 January 2015

Michael went out to the boat today to take out 80 litres of water and some cleaned linen. He also added the fuel to the main tank, but forgot to take the new siphon hose! He also forgot to check the size of the prop on the outboard! His excuse, it was extremely hot and humid and he had to get back to the air conditioned car. Perhaps tomorrow when he goes out diving he will check the prop (he did, it is a 9 inch prop with a 9 inch pitch).

13 January 2015

Michael again went out to the boat. He took another 80 litres of water with him, but only added about 15 litres to the starboard tank before it was full. He also remembered to take the diesel jiggler siphon, which of course he does not need to use till he takes more fuel out later. Kelly gave him a lot of things to take out, including food items for the Australia Day weekend, some collapsible bags which will be used to store recyclables and transferring linen back and forth.

One of his other tasks was to tidy up the ropes we attached to the sun shade two weeks ago. He took with him a fancy soldering iron and used this to melt through the ropes. This works perfectly, leaving nice clean ends. He also tidied up some other pieces of rope.

|  |

| The multiplexer Michael has partially installed | This is the soldering iron Michael used to cut the

ropes, you can see the clean cut |

Michael also took out the Seatalk/NMEA-0183 Bi-directional Bridge and attempted to install it. He cut the Seatalk cable in half (this may have been a mistake - see later) and managed with a lot of difficulty plug it into the depth instrument (there is little room behind the panel). He also pulled through a cable from under the saloon seat to the helm area and soldered it to the cut Seatalk cable.

He then connected the Seatalk to the bridge/multiplexer and also the serial/USB cable. He got the serial/USB cable to be recognised by our navigation laptop. However, he has not yet been able to get the multiplexer to connect to the laptop using the serial terminal program Termite. The program recognises the AIS and GPS inputs from the other COM ports, so he is not sure what is wrong.

After almost five hours on the boat he decided he had had enough so he came home.

16 January 2015

Michael and our friend Paul Pacey went out to Catlypso early to try to remove the wind generator. This is an AirX Airmarine but has never worked since we got the boat (we knew this when we purchased it). However, after unbolting the pole on which it is mounted, they discovered a bracing bar under this that was also bolted. Even when these bolts were removed, the pole could not be budged. We suspect that there is adhesive of some sort holding it in place. As well, they did not want to force it in case it damaged the gelcoat.

|

| This shows the wind generator as we pass Bare Island |

Plan B will now come into force. We will now take the boat to the wharf and tie her up. Paul will bring some fancy ladders cum scaffolding and set them up on the wharf. We will have another dive buddy, Eddie, who will assist. Then we will remove the wind generator from the top of the pole. We estimate that this will not take long to do, but as it is school holidays at the moment, we will put this off till early February when all the kids have gone back to school and the wharf is quieter (since we need to block the whole main side of the wharf). In fact, this did not happen till March as the weather did no co-operate when everyone was available.

17 January 2015

As readers of our pages about Catlypso will know, we started using a commercial mooring in Yowie Bay when we returned from Queensland with the boat. In the meantime, we put in for a mooring from Roads and Maritime Services. This was allocated back in November 2014 and we picked a spot later that month for the mooring. Michael arranged for it to be installed and on 23 December 2014 we were advised by the mooring contractor that it had been installed.

After we returned to Port Hacking after our Christmas/New Year on Broken Bay, we decided to stay on the commercial mooring for a week or so till we had examined the new mooring. However, when Michael went out there after a dive, he discovered that the mooring was not in the location allocated to us and there was another mooring where we should be. To make matters worse, where our mooring was installed had insufficient room to put even our six metre power cat, let alone a 12 metre one.

Michael contacted the RMS Boating Service Officer for Port Hacking and on 17 January 2015 she rang us from the site. She agreed that our mooring was not in the right place and there was indeed someone else where we should be. She contacted the mooring contractor and advised him he needed to fix the matter up.

Hopefully this will be fixed by next week as we have cancelled our commercial mooring as from 31 January 2015 (it was not).

23-26 January 2015

When we went out for the Australia Day long weekend, we determined that the autopilot was now working okay. Wee used it a couple of times when sailing from Port Hacking to Botany Bay and back.

Michael also installed the new 7 inch pitch prop on the tender's outboard. However, when he went to collect our guests from the wharf, he was not able to get up on the plane with four on board (and lots of gear). Even with three on board and some gear it did not get up on the plane any easier. Very disappointing! Michael proposes to remove the large hydrofoils on the outboard. From experience, he has seen that sometimes these actually reduce the efficiency of the motor.

|  |

| The two GoPro type cameras we purchased | The bow seat removed and the new piece

we purchased to make into a starboard seat |

Michael also noticed in the local paper that Aldi was selling GoPro type cameras (Onix Action Camera)for $20 at the local store. However, this was from 24 January when we will be on the boat. He had to do some shopping for meat at Hurstville and while there, went to the Aldi store. They had the cameras for $25 so he bought two. They come with waterproof housing (albeit only 3 metres), come with two different mounting systems, have a screen and do video and photos. He mounted one next to the helm and tested it a couple of times over the weekend. The quality was good enough for what we want.

|  |

| Kelly cleaning out the anchor well | The rear sun/rain shade |

Kelly also cleaned out the anchor locker and we rearranged the spare anchor, rope, chain etc. Another thing that we knew we had but had never used was the rear shade/rain curtain. This hangs from the cockpit roof and zips into place. As we had a couple of very hot days when the sun was shining right in here, we put it up. It is in good condition. It also seems to have some "doors" for each side, we are not yet sure if we have these bits.

29 January 2015

Today we attended a Diesel Engine Maintenance Course run by Offshore Maritime Training Australia. This was held at Mosman next to the Mosman Rowing Club. There were nine people at the course, some had travelled from Melbourne and Canberra for it. During the course we were taught the principles of diesel engines (particularly marine diesel engines) and how to maintain our engines.

We also found out something that we did not know. We had thought that the saltwater for the engine cooling came though a seacock on the port side. Well, we now know that it does not, it comes though the saildrive leg and the seacock is on the leg. This is a bit of a pain in the arse as it is difficult to get to the engine room if carrying a bit of extra gear.

Anyway, we thoroughly enjoyed the course and would recommend it to anyone interested in understanding how their engines work and how to maintain them.

30 January 2015

Readers of our web site would be aware that during our delivery journey from the Gold Coast in July last year, we lost the seat on the port bow. This happened because it was held on by three screws that only went a few millimetres into the seat and when hit by a large sea, it was ripped off and went overboard.

Since then we have not worried about replacing it, but last week we removed the starboard one from the boat. Michael attempted to find out what material it was made from and where we could get a replacement. The seat is about 63 cm long and 33 cm wide with a triangular shape at one end.

After a lot of searching on the internet, Michael came to the conclusion that it was a product called Vycom Seaboard. The weight of this product came out to within 100 grams of the weight of the remaining seat when it was calculated. A company called Allplastics Engineering located at Chatswood in Sydney stocked it, so today Michael took the remaining seat and went there.

They confirmed that it was Seaboard, but the bad news was they had no 19 mm in stock and while they had 16 mm, we would have to buy a whole sheet of it (they had no off cuts) which is 1220 x 2440 mm. We only need 15% of a sheet but would have to buy the whole thing. The cost was going to be almost $700 ex GST! No way. Michael found some other suppliers on the internet and emailed asking if they had an offcut. If not, we may need to look at a marine ply alternative.

2 February 2015

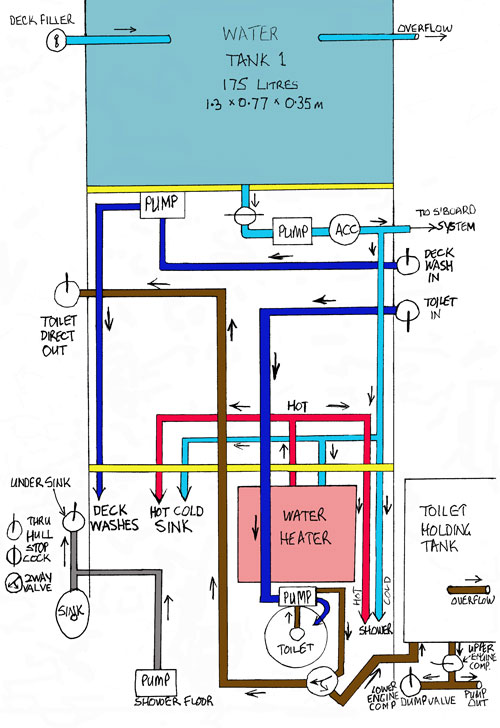

Today Michael finally finished the diagrams which show the plumbing for the fresh, salt, grey and brown water plumbing for the boat. He started this work way back in June 2014, then lost the diagrams on the trip down from the Gold Coast. He had to redo them later. Since then, he had not finalised as he was still not certain that it was correct and complete. Sure enough, we discovered that there was one more thru-hull that we were not aware off (under the bathroom sink) and that the cooling water for the engines did not come in the way we thought it did. Anyway, the diagram below details the layout.

|  |

The water diagram for the port hull

Click to enlarge | The water diagram for the starboard hull

Click to enlarge |

Also today, Michael sourced the spare parts we need for the two Yanmar engines. He ordered the following:

Oil filters x 4

Fuel filters x 4

Impellers x 4

Alternator v-belt x 2

Water pump v-belt x 2

As we have no idea when any of these were last changed, we will be doing a full change (and oil) in the next few weeks. This will then also give us spares to do another oil change and fuel filter change if we need to do on our 2015 trip. We will also have backup impellers. We will keep the old impellers and belts as spares if they are in reasonable condition.

He will pick them up from Power Equipment at Taren Point in Sydney (Link to web site) tomorrow. Total cost was $645. He has already purchased the necessary oil a few months ago when he saw it on special.

|

| Our pile of spares so we can service the engines |

After getting a couple of replies to his email about Seaboard, today Michael got one from a company in Brisbane that had an off-cut for $90 plus freight of $35. He ordered this. Kelly's Dad will shape it to match the other side.

4 February 2015

Today we were told by the mooring contractor that our mooring was now in the right place. He advised that he had mixed up the "mud map" of where the moorings were to go and put ours in the wrong place. He says it is fixed. Michael will attempt to go out on Friday and check it out (tomorrow is going to be too windy). As of 7 March we still have problems with this that I will not yet detail.

5 February 2015

The piece of Seaboard arrived from Brisbane via the courier. Michael gave it to Tomas, Kelly's Dad (who was visiting). He will form it into the correct shape over the coming days.

6 February 2015

Well, that was quick, Tomas brought back the bow seat shaped to fit. Now we need to drill the holes and bolt it to the frame. Michael will do this over the coming week.

Prior to this, Michael went out to Catlypso. He took out four Jerry cans of diesel (93.5 litres) and filled the tank, it is almost full. He also took out 80 litres of water and filled the two water tanks that were not full. He also took out clean linen etc.

While he was there, he took Thunderbird 2 and ran up to the spot where our new mooring is supposed to be. Woohoo! It is now in the right spot and also there appears to be more than sufficient room for us to fit. We will move the boat tomorrow afternoon we hope. Michael also used his portable GPS and measured how far it is from the wharf to the mooring, 420 metres. A bit more than now (which is about 350 metres in a dogleg), but not too bad really, could have been a lot further.

7 February 2015

This afternoon we moved Catlypso to her new mooring. We were not sure how we were going to hook her up, as the mooring lines were a bit different. The new one has two lines, but we are not sure if they would even reach to the bollards on each bow. In the end, Kelly decided to use our mooring bridles and put them through the two loops. Seems to work okay and the added length does not infringe on our closeness to the boats near us. We have plenty of room between the closest boats, at least 15 metres I think.

13 February 2015

Michael took the new bow seat as well as the old one out to the boat. Thanks to our neighbours Kim and Gerard, we have the necessary stainless steel bolts to attach the seats to the bow rail extension. Previously they were attached by screws from underneath. However, as the seats are only 19 mm thick, this meant that less than 9 mm of screw was in the seat, and even less actually holding. This is why the starboard seat was lost, the screws just wore loose and then fell out.

What Michael has done now is to drill new, larger holes all the way through the seat material. He also enlarged the holes though the support base. He then drilled a countersink in each hole. We got 5 mm x 50 mm long countersunk socket screws bolts with nylock nuts. This means the bolts sit flush with the seat and will not intrude on your bum! He drilled new holes in the new seat and successfully attached the seats. Appears to work well.

While out there, Michael attempted again to get the new Seatalk/NMEA-0183 Bi-directional Bridge working from his failed 13 January 2015 attempt. However, he was not successful. The computer recognises that it is connected to the laptop via USB, but attempts to connect to it using a data program have failed (the program is working as it connects to the GPS and AIS). He will start from the beginning and see where he has gone wrong.

Michael also reinstalled Memory Map as the installation on this laptop is not working 100%. The problem is that it will not record a track. He attempted to get advise from the maker yesterday but all they offered was the obvious (which he had already checked). Without moving the boat it is not clear if this worked (two days later we went sailing and it recorded part of the track but not all - still not fixed).

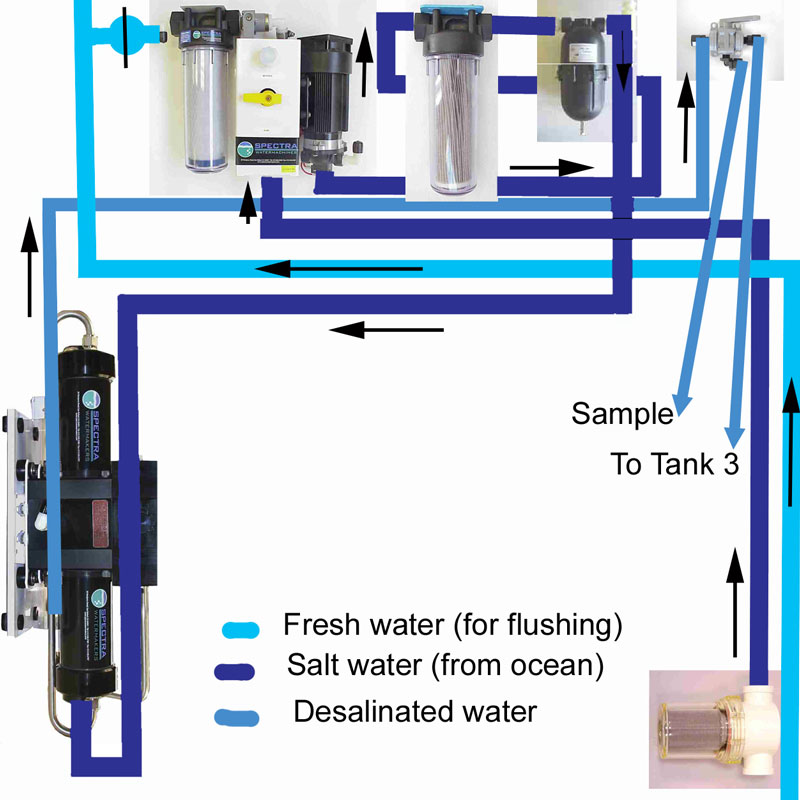

He also drilled a 20 mm hole in the plywood base of the double bed (starboard stern). This has been almost impossible to lift as there is nothing to grab hold of. While he had this open, he drew a diagram of the Spectra Watermaker system and will make a nice diagram for reference. He also discovered that behind this compartment there is another plywood base that when lifted gives access to the front part of the upper engine compartment. There is also a light here that we never knew existed. Wonder if there is one in the port compartment as well? (there does not appear to be)

|

The plumbing diagram for the watermaker

Click to enlarge |

Michael also lifted the floor in the galley and discovered a fair bit of water there. It was fresh, so he thinks that when he filled the water tanks on that side, the overflow may have got in there. This is the only apparent way water could get there as far as we can see. He had thought back on the delivery voyage that water entered that side when he filled those tanks at Camden Haven via a hose. We need to explore this a bit more.

That was enough time on the boat, we are going sailing on Sunday (two days time), so will be back out there then and may do a couple of other things.

15 February 2015

Today we went out to Catlypso relatively early (considering we went out for a late Valentine's Day dinner last night). We left the mooring at about 0930 and motored out to Bate Bay which is the start of the Pacific Ocean/Tasman Sea. Once here we raised the main sail and the screecher. However, the wind which look promising (forecast was 10 kts NE all day) proved to be a disappointment. In the end we pulled in the sails and motored the rest of the way to Botany Bay.

Once again we anchored to the east of Bare Island, this time off Congie Beach (Congwong Beach). We had lunch here and did a few things on the boat. One thing that we mentioned two days ago was that we had some freshwater in the starboard holds. Well, there was more again today, and some on the floor. We are stumped as to where it is coming in. We will need to check a bit on this. We had more rain since Friday, so it might be leaking through one of the windows as there is some water on one.

We moved a lot of the tools and spares into different boxes. We also have to get a another hard box to replace the one that holds spare parts.

At 1400 we departed Congie and sailed back. This time we had between 8 and 10 knots of wind, ENE or so. This pushed us along at a very nice 7 to 8 knots. However, when we were level with Port Hacking, the wind dropped. We jibed back towards land but withing 20 minutes we gave up and dropped the sails. We had less than 4 knots of wind. All in all, a very pleasant day.

21 February 2015

Today we purchased two more diesel Jerry cans. They were on sale for $25 at Repco, a bargain, $15 off. This now gives us five, so we can carry an additional 100 litres (really, 110) of diesel in addition to the 200 litres in the tank.

22 February 2015

We went out to Catlypso today to do a couple of things. One was to attempt to test removing oil from an engine with the device we found on the boat when we bought it. However, even after pumping dozens of times, we only got a dribble of oil out. Looks like we need a proper pump (which we purchased later). Michael also identified the primary fuel filter (which is not Yanmar) and the air filter so we can purchase replacements.

Kelly measured the size of the chain (10 mm) as we need to purchase at least some new chain as a large section is very rusty. Michael also pulled out some more canvas pieces that have been stored in our cabin. These are as follows:

|  |

| The large mesh section. The "doors" fit in the gap here | One of the new Yanmar air filter |

We also took out some storage racks that Kelly purchased. These fit in cupboards and provide better use of the available space.

On the way home we went to the local boating shop and purchased a dedicated oil pump, another grab bag and some rust stain remover.

A worrying thing was that Veto fell in the water today. She was on the port transom when Michael started the engines. It seems that when the first lot of cooling water came out of the engine it scared her and she jumped a bit and fell in the water. Michael heard her fall in and quickly was on the spot. She swam around for a bit before coming close enough to be grabbed. We had already decided that we need a "gate" between the cockpit and the transoms to stop her wandering. Kelly will now organise this as a priority.

23 February 2015

Michael purchased two primary fuel filter cartridges (which are Ryco R2132P). These fit in a larger filter container called R2132UA. He was going to get four so we had two spares, but the auto shop only had two (he got two the next day at a different branch of the same store).

He also tried to identify a replacement for the air filter. The filter has no identifying marks on it at all, so we had no idea what brand it was. However, after a bit of searching and looking at a parts manual for our Yanmar engines, we think it is actually a Yanmar filter. The price of the filter is exorbitant, considering it is just a bit of foam over a metal frame/silencer. He is going to see if he can find some foam that he can cut and fit to the silencer.

25 February 2015

Well, Michael gave up on finding foam for the air filters. All the Clarks Rubber stores that used to be near us have closed down. The fuel cost and hassle to drive across a good part of Sydney to get to the nearest one would probably outweigh the money saved. So, Michael went to Power Equipment at Taren Point (where he got the other Yanmar parts) and purchased two filters (part 128720-12540) for $42.35 each. Good service from this company in case we have not already mentioned it.

|  |

| One of the polo shirts we had made | A close up of the logo on the shirts |

Also today our T-shirts arrived. Michael designed a logo and had a bunch of shirts made with embroidered logos. They are white polo shirts, not the greatest quality, but they will do. We only intend to wear them when going to sundowners with other yacht owners. See the photos of the shirts above. We ordered them from Vistaprint, a good service. Cost was $15 each delivered, but they were on special.

28 February 2015

Michael dropped Kelly off at the boat this morning as he went out diving. Kelly took out a few more things that we purchased. Her main aim this morning was to show a marine upholsterer the helm canopy. This is starting to fall apart and needs replacing. As we suspected, it is beyond repair. They will provide a quote on making a new one. We also got them to quote on making two "gates" to keep Veto in the cockpit.

While out there, Kelly replaced the engine air filters and cleaned the storage compartments under the main saloon seats. She also moved the spinnaker out of its current location under the seats.

1 March 2015

We went out to the boat today with the aim of doing engine maintenance. We started on the port engine as it appears to be the easiest to access all parts. This is because there is a hatch from the shower which opens at the front of the engine.

Michael first removed the engine oil using our new oil pump. Luckily we did not throw out the old one, as the sucker hose (not sure of real name) was too thick to fit down the oil dipstick pipe. The thinnest hose from the old one fitted inside the new one and worked. We got all the oil out fairly easily, although we did some more after changing the filter as more had dripped down.

The oil filter was a bit harder to get out. It could not be loosened by hand and as we did not have a filter wrench, Michael had to hammer a screwdriver through it and then turn it about 1/8 of a turn. He did it again and then, with a very small screwdriver, he could turn it till it was free.

Then it was just a matter of putting the new filter on, adding oil, checking, running engine to fill the filter and adding some more oil. Next he removed the primary fuel filter. This is easy to access and easy to disassemble. It was a little hard to remove some of the o-rings, and the kit that came with the new filter did not have enough o-rings to change them all. It looks like the glass bowl at the bottom is an extra and there was no o-ring for it. We picked the best of the old o-rings and used that.

|  |

| Michael in the confined space of the upper engine room | The primary fuel filter top right, the bucket

collecting the diesel as it is opened below.

The air filter is the black thing at bottom. |

The fine fuel filter is part of the engine. This is harder to get at, although we later discovered that it is easy to access via the shower. Anyway, Michael removed it and put the new filter on. However, we think that we neglected to put in a new o-ring, we need to check this and do later if there was in fact a new one.

Michael also discovered where the raw sea water intake valve was (on the sail drive) and with the help of a pair of multi-grips, he loosened it and the closed it by hand. He then removed the top of the raw seawater filter and cleaned this. There were a few small shells inside.

From the shower, he then removed the screws/bolts that hold the seawater impeller cover in place and then pulled out the old impeller. This was still in very good condition, so we will keep it as an emergency spare. He then installed the new impeller.

The last thing to do on this engine was replace the v-belts. There are two. A larger one which runs the freshwater pump and the alternator. There is a smaller one behind this which runs the seawater pump. To access the larger one, you need to loosen the alternator (fairly easy) and then remove the seawater hose from its bracket. The old belt then comes off.

|  |

| Michael accessing the front of the engine from the shower | TO COME |

However, we could not work out how to free the smaller belt. The manual does not even mention that there is a second belt, let alone how to loosen it and remove it. We decided to just replace the larger one now and investigate how to do the other one.

Michael opened the fuel cock in the engine room and soon the primary filter was full and overflowing. He then loosened the bleed nut on the top of the fine filter and fuel soon came out. He tightened the nuts up and Kelly started the engine. It took four goes before it started while it sucked the fuel in. It ran rough for about 30 seconds until all the air was out of the fuel system. It then ran smooth.

We checked and had water coming out of the exhaust, no leaks in any of the replaced items. However, the v-belt was a bit loose so we stopped the engine and tightened it a bit. It is almost at the end of its adjustment, so we hope it does not stretch. Another short run of the engine and the belt was much better, although we will check it again next time we run the motor.

All of the above took about three hours to do. We think this is not too bad considering we had never done this before and that we learnt some shortcuts. Michael will do a few of the items on the starboard engine when he next goes out (oil, oil filter, fuel filters and water filter) as he should be able to do these without assistance. The belts will be done next time we are both there.

A very productive day.

2 & 3 March 2015

Michael started shopping for food today for our trip, purchasing items that have long shelf lives and that are on special at the supermarket. Things that he got include powder milk (which has been in very short supply in Sydney for the past couple of months), orange juice, vegetable oil and a few more things. Hopefully we can get most of our non-perishables over the coming month.

He also purchased a cheap rice maker. This appears to not use too much power, so long as the stated wattage is correct. Time will tell. He also purchased a fishing rod for trolling. Michael does not eat fish, but Kelly does, so it will hopefully get some food for her!

5 March 2015

Michael went out to Catlypso today very early as there was a southerly change forecast to come in mid-morning. As this is the worst wind for where we are moored, he wanted to get as much work done as he could before it came up so that his trip back to the boat ramp was not too wet.

Today's aim was to do maintenance on the starboard engine. He got out there just after 0830 (with Veto) and started the engine to warm up the oil. He also took out some of the things (mostly food) he purchased earlier in the week. He also turned on the fridge as we are spending the weekend on her in just over a week.

The oil change went very smoothly, the oil came out easily and the oil filter came off by hand, no need to use the oil filter wrench Michael found at home. The raw sea water filter was cleaned and put back together also without out too much problems, but more about this later!

The primary fuel filter was a little harder. Unlike the one on the port side, this is shoved right up under the floor. This means that the bolt that holds it together is very hard to access, although using a spanner rather than an adjustable spanner meant he could do it. However, the fuel bleed nut is almost impossible to get to, in fact, he did not even try. He instead undid the bleed nut on the fine fuel filter which let the fuel run out the drain hole.

He was able to catch most of the fuel in a container. He removed the parts of the filter, cleaned the glass bowl and replaced the o-rings and put in the new filter. However, he was not able to remove the bolt and change the small o-ring at the top. This is because there is insufficient room to take it out the top! Why did they not put it down another 10 mm? He put it back together.

The fine fuel filter was easy to get off, but it is hard to catch a lot of the fuel. This time Michael remembered to replace the o-ring at the top of the filter housing, we did not do that on the port one. Once the filter was replaced and all put back together, he bleed both the filters by undoing the fine filter bleed nut. This filled both the filters.

We had already decided that Michael would not change the v-belts, but he would change the impeller if he was easy. It is not! There is little room to access the cover as there is no access from the front. Michael turned on the raw sea water valve (which is on the sail drive). When he did this, water ran out the filter. He tried tightening the nut but it still leaked. He removed the cover, cleaned the o-ring and tried again. Still leaking, this time worse.

He did this about four or five more times without success. He remembered that there was a spare filter in with the spare parts. Opening it up he found a number of new o-rings. He took one and replaced the old one. This time the water did not leak out. Now it was time to start the engine. First attempt it ran for 10 seconds. Second attempt it kept running, his bleeding both filters via the fine fuel filter obviously worked.

However, there were bigger problems, there was no water coming out of the exhaust. He stopped the engine and checked everything. It all looked okay, so he tried again. Still no water. The next time he let it run a little longer to see if perhaps it took a while to build up enough water. No good.

Michael thought that perhaps the diesel from the fine fuel filter dripped onto the pulley behind the water pump and it was slipping. He found that he could turn the belt which turned the pump. It looks like it is a bit loose, we will need to tighten it when we change the belt. Anyway, when he started the engine this time, the water came out the exhaust. What the hell?! Perhaps it was slipping and when he moved the belt it started to grip.

Michael checked everything and there were no leaks from the oil filter, fuel filters or the water filter. He turned off the engine and put all the tools away. By now the southerly change had hit and it was getting quite windy, so he wanted he head back to the boat ramp as soon as possible. He cleaned up, put all the rubbish in the dinghy and with Veto on his lap, motored back to the ramp. On the way home he went to the local marine equipment shop and purchased a hatch flush pull to replace the broken one on the starboard engine room hatch.

All in all, a successful morning.

6 March 2015

Today Kelly went and had a test on her heart to check if the operation to close the PFO (hole in the heart) that caused her to get decompression sickness last August when we were diving in Indonesia. Good news, the hole has completely sealed over and she can now scuba dive again. Six months without diving has been like torture to her. Unfortunately she probably will not get to dive till the weekend of 21 March due to other commitments. She also later got clearance from the diving doctor to restart diving.

Michael applied today for a marine radio licence for Catlypso. This is so we can get a licence number and use the HF radio. He hopes he has used the right form and completed it correctly, but as the ACMA (Australian Communications and Media Authority) web site is possibly the most complicated, obtuse and poorly set out web site we have seen for 10 years, we have no idea. You cannot even complete the form on-line and payment is expected by cheque. Who the f**k uses cheques in 2015?

Anyway, he scanned the completed form and emailed off to an address that implies will accept applications. He hopes that he can pay later via a transfer, as he did find a page on their web site that mentioned this. He also has no idea of the cost of the licence as all the links go around in circles rather than straight to the information that is being talked about. We will update the page when we know more.

9 March 2015

Well, we finally had good weather for the day that we planned to remove the wind generator from the boat for repair. A previous attempt to remove it (an AirX Airmarine) when on the boat failed as it was too hard to take down the pole on which the generator is mounted. Plan B, to take Catlypso to the wharf and use scaffolding on the wharf to remove it, had been cancelled multiple times since early January due to bad weather. We needed an almost totally wind free morning on a weekday (since we needed to block all of one side of the wharf), something that has not been all that common in Sydney this year.

Anyway, Michael met our dive buddies Eddie and Paul at the wharf at 0730 and Michael took Eddie out with him to the boat while Paul set up the gear. They were almost at the boat when the engine on the little dinghy, a cheap Chinese 2 hp failed. It looks like it might have seized, no idea why when it has had proper fuel all the time. A passing fisher towed them the last 100 metres.

After setting up the fenders and mooring ropes, Eddie cast off the mooring and Michael motored over to the wharf. They quickly tied up alongside, using another rope to make sure the stern was pulled in closer to the wharf than would normally happen. Soon Paul was up the scaffolding (really a fancy ladder that can be made into a simple scaffold) taking off the generator blades. These came off easily, although one will require some repair as it has a crack near one of the bolt holes.

|  |

| Paul on the scaffolding and Eddie assisting | Inside the wind generator. The inductor that was

broken off the circuit board is the large round

black item at the bottom. |

The generator itself also came off fairly easily, the hardest thing being to feed the cable up the mounting pole with a rope inside so we can pull the cable back down when we remount it. We also attached a rope to in and tied off to the pole so that in case it was dropped, it would not fall onto the boat or wharf, or worse, into the water.

Anyway, by 0830 we had it off and left the wharf to take Catlypso back to the mooring. Of course, we had to row back to the wharf at the end! Thanks to Eddie and Paul for helping to remove. Paul now has the generator and will attempt to get it running.

There are a couple of good quality second hand 2 hp outboards on sale on eBay at the moment closing tonight. Michael likes one in particular and will bid for it. Remember, never buy one of these cheap Chinese outboards, dead after less than 20 hours running.

Later in the afternoon Michael purchased a bunch of fishing gear to go with the fishing rod he got last week. He got some squid jigs and a few trolling lures as well as steel trace and line.

Paul had a look at the wind generator later in the day. He emailed Michael that night and advised that he had found the problem (well, actually a couple of problems) which were easily fixed. The main reason it was not working was that the inductor had broken its solder joint to the circuit board. Once connected, when tested (using a drill to spin the shaft) the generator charges a battery and when the battery is full, it slows the generator down.

Also, the LED was not working due to a corroded connection, also easily fixed. Some bearings will need replacing, but hopefully it will all be fixed later this week. Fantastic work by Paul, our dive club's (retired) electronics wizard.

10 March 2015

Paul ordered the bearings and o-rings to bring the wind generator back up to almost brand new condition. He will collect tomorrow.

This afternoon Michael drove to Wilton, about 55 kilometres away and had a look at a Mercury 3.3 hp two stroke that was for sale on Gumtree. The engine was serviced, with new impeller and spark plug and more, a few years ago but according to the owner, has only run for about two hours since then. The cost of the service was $285!

|

| The small dinghy and the "new" 3.3 hp Mercury two stroke outboard |

Anyway, it looked in very good condition and started first pull. It weighs a few kilograms more than the Chinese outboard, but also has 65% more power. It also has gears rather than a centrifugal clutch. Michael purchased it for $400. As well as the engine, he got a five litre fuel container and a trolley to store it on. Considering he has seen 2 hp good name motors go for about this on eBay, and four strokes for more than double, we think (hope) we got a bargain.

11 March 2015

Well, at least ACMA is reasonably efficient in processing applications for marine radio licences despite having a useless web site and very confusing documentation. Today we were emailed our radio call sign. We are now VJN4818. The cost turned out to be $55. I presume that this is for one year, but I am sure that I nominated two years for the licence. The paperwork at least gave a indication of how to pay, including by credit card via the web site (although I am not yet convinced that it will be easy to find).

Paul emailed Michael and told him the wind generator is now back together. However, he is going away diving next week so it will not be able to be reinstalled till the week of 23 March 2015. Again, we will need a very calm day so we can put it back up. Hopefully we will not have to wait as long as we did to remove it.

13-15 March 2015

We went out on the boat on the weekend as Michael's sister Janelle, her husband Karl and their kids Joshua and Isabelle were coming for a stay. On the Friday Michael entered the call sign into the AIS and later on the weekend was able to confirm that it worked okay.

On the Saturday evening when Michael came back from taking Veto for a pee, he noticed that there was some oil sheen on the water's surface next to the starboard stern. He opened the engine compartment and found that the sea water strainer was leaking. He removed the lid and found that the top of it, where the wingnut held it onto the body, was broken. This is a clear plastic and parts of it had shattered. Luckily we have a spare one (remember Michael used one of the o-rings last week) so we took the lid and replaced it. Not leaking now.

After we returned home, Kelly went and purchased some large hooks. These will be screwed into some of the left over plastic from the bow seat. These will then be stuck to the inside of the anchor well using an epoxy. Hopefully this will work okay.

Also on this weekend we used the new Mercury 3.3 hp on the little dinghy. Runs great and is very quite compared to the crap Chinese one. Also has a lot more grunt (as you would expect).

19 March 2015

Michael made up four hook devices to go in the anchor well. These are stainless hooks that he screwed onto four rectangular blocks that he cut out of the bow seat material. The blocks will be stuck to the side of the well using a two part epoxy glue (same as used for the trampolines).

|

The new filter cartridge at left, then the replaced one. At back one of the hooks for the anchor well.

Right and front, the new raw sea water strainer and the broken lid. |

He also purchased a new raw sea water strainer. This is to replace the lid of the spare one which was used to replace the broken starboard one. Another thing he got to day was a charcoal filter cartridge for the watermaker. This filter removes chlorine from town water so that it does not damage the membrane when flushing the watermaker. Bunnings had plenty of different ones that all fit the filter.

21 March 2015

This is not exactly related to the work on the boat, but today Kelly did her first dive in seven months. She has not been able to dive since August 2014 when she got bent in Bali. This was caused by a PFO (hole in the heart). She had this repaired by surgery just over three months ago and was given medical approval to dive again this week. All went well and she was very relaxed. Woo hoo!!!

22 March 2015

Michael and our dive buddies, Paul and Eddie, went out to the boat today and reinstalled the wind generator. The actual work only took about 20 minutes, but by the time they launched and retrieved the dinghy, motored to Catlypso, moved her to the wharf, did the work and took her back etc, it took just over an hour. As you can imagine, it was was a very painless bit of work. Total cost of the parts was $41.

|

| Paul with the reinstalled generator |

While Catlypso was at the wharf, they also removed the washing machine and put it in Michael's Prado. Michael also put a large amount of food for our trip on board.

24 March 2015

Michael finally worked out how to remove the pulley from the electric motor on the Bauer Junior II dive compressor (you need to tap the outer part of the pulley back after you remove the grub screws). However, this created a new problem, the shaft on the Honda engine is smaller than the shaft on the electric motor. This means we will need to get a different pulley.

He also purchased some plastic tubing to go on the end of the PVC pipe that we insert in the compressor's air intake. The tubing will run forward into the wind so that we do not suck in any carbon monoxide when filling tanks.

Michael also ground down the broken lid of the raw sea water strainer so that it can be reused as a spare in an emergency. We have a new lid, but this will be a backup.

Click here for the second part of this article

Return to Our Yachting Adventures

|

v6.00.307 © 2003-2005

v6.00.307 © 2003-2005